VUB scientists seek sustainable alternatives to concrete

Three research groups at the Vrije Universiteit Brussel are working together in a major European project exploring new alternatives to concrete. Architectural Engineering (ARCH), Mechanics of Materials and Constructions (MEMC), and Physical Chemistry and Polymer Science (FYSC) are joining forces for the Reconstruct project. Standard concrete construction requires a lot of energy and raw materials and thus has a significant environmental cost. The Reconstruct project aims to improve the composition of concrete, introduce more modular building systems and improve traceability through a materials passport for every building. The project is supported by 16 European partners and funded under the EU’s Horizon Europe research programme.

“We are experimenting with concrete that incorporates elements other than the traditional ones,” says VUB professor Hubert Rahier. “The materials that make the biggest contribution to concrete’s environmental impact are cement and reinforcement steel. So, with the Reconstruct partners, we are testing low-carbon, low-impact alternatives. These could be recycled products from the demolition of concrete structures or other recycled materials combined with textile reinforcement. We hope to eventually replace both these base elements.”

To eliminate cement from the production process, the VUB team is developing an innovative concrete that uses alkali-activated cement. It incorporates granulated blast furnace and pretreated biomass ash. “With this material, we can cut up to 80 per cent of carbon emissions compared to ordinary cement,” says Rahier. “Its production also contributes to the circular economy, as it contains large quantities of industrial by-products.”

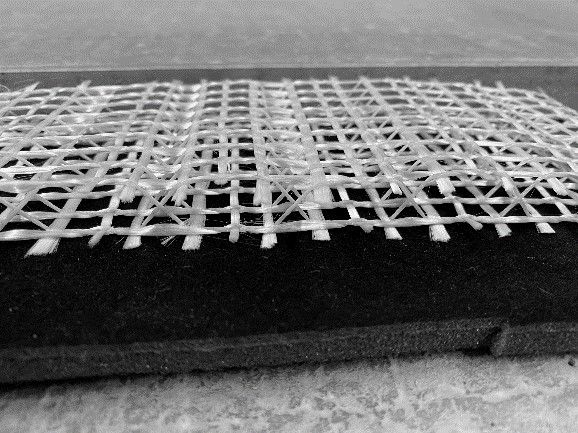

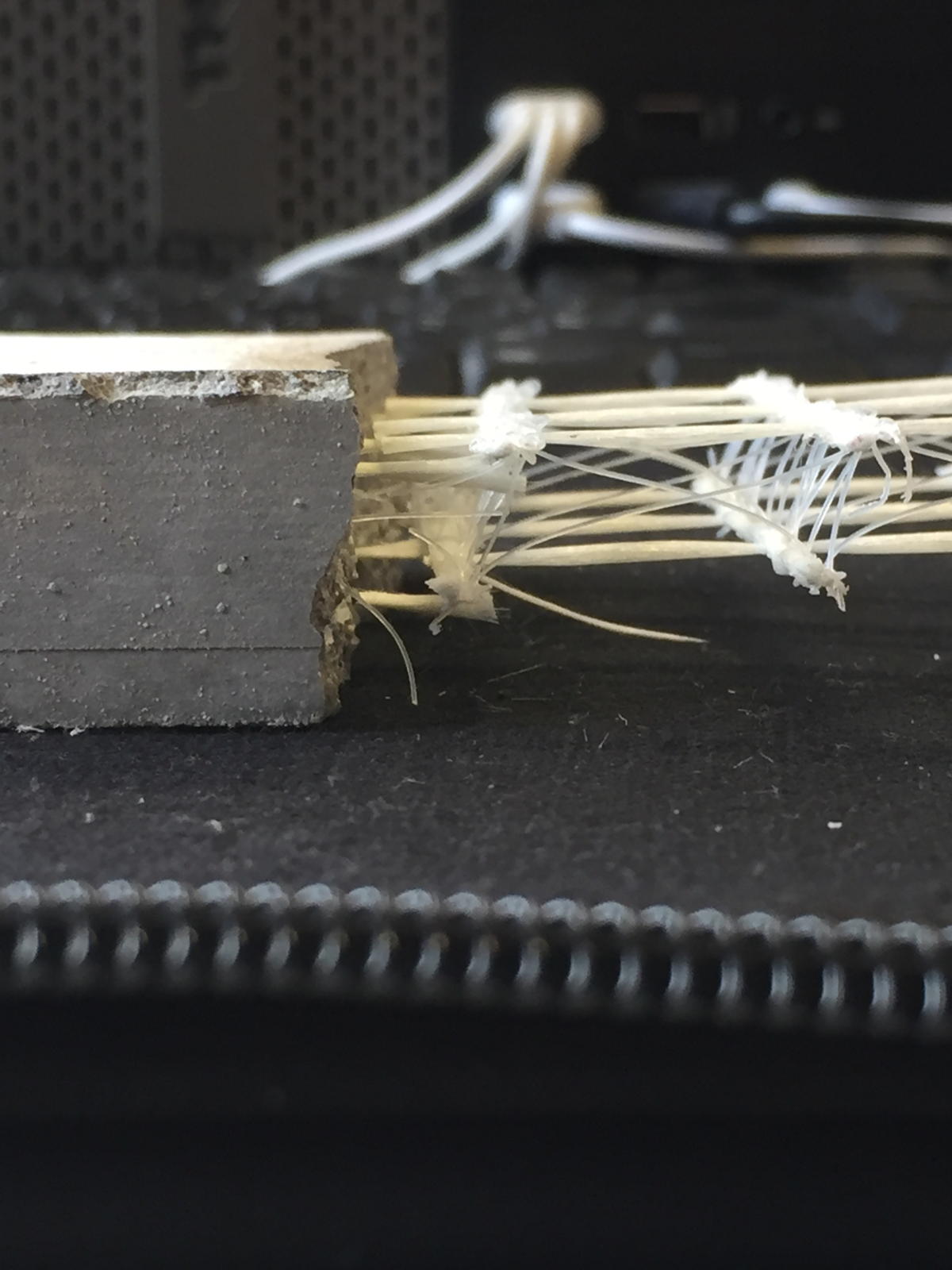

VUB is also working with local construction partners to develop a lightweight, modular floor system that uses not only recycled concrete but also textiles such as glass fibre to replace the reinforcing steel. “In traditional concrete construction, you need a thick layer of concrete cover to prevent the steel from corroding,” says professor Tine Tysmans. “You don’t have that problem if you use glass fibre as the reinforcement, meaning you can make much thinner concrete. This means not only that fewer raw materials are needed for concrete elements, but also that the foundations are lighter, so there are ecological and economic gains during the transport and construction process.”

Changing the composition of concrete is only the first step. We also need to learn to reuse concrete. “On the building site, concrete structures are often cast together to create one large monolith. After demolition, we can then only recycle the basic materials,” says researcher Jeroen Poppe. “Disassembling the structure for reuse is unnecessarily difficult with poured concrete.”

The Reconstruct partners therefore advocate a shift to dry construction and modularity in the design of concrete structures. By dry-stacking standard prefab elements, it should become possible to disassemble the building completely instead of demolishing it. “The more generic the elements, the more easily they can be reused in another setting afterwards,” says Poppe.

VUB will test how prefab construction systems can make a difference with a demonstration at the Green Energy Park in Zellik. A building will be erected for that purpose, which can be disassembled in sections. Individual parts will then be replaced with new, circular concrete elements and tested for strength and durability.

To complement its technical strategy, Reconstruct is also applying digital techniques: using product passports and digital twinning, they want to track materials along the value chain. “With digital tools and AI-based technology, we want to help build predictable, local supply chains for reclaimed materials,” says Poppe. “This allows us to see at any time where existing components will become available in the construction chain, what action we need to take to recover them and how we can reuse them in new buildings.”

More information

Jeroen Poppe: +32 473 82 40 03

Hubert Rahier: +32 494 12 99 63

Tine Tysmans, Michael El Kadi, Gulsen Nazerian, Niels De Temmerman, Waldo Galle